A guide for manufacturers going solar

Manufacturing requires power. The Energy Information Administration (EIA) reports that the industrial sector, including manufacturing, accounts for 35% of total end-use energy consumption in the U.S. Even accounting for efficiency efforts, with more manufacturing processes automating, energy use is unlikely to go down anytime soon.

The EIA also notes rising energy prices across the nation. From 2012 to 2022 commercial energy prices rose over 24% and industrial energy prices rose over 26%. For over a century, as the only game in town, local utilities have set energy pricing – and rising prices have been passed along to the manufacturing sector as part of the cost of doing business.

As energy prices have risen, partially driven by an international demand for natural gas and petroleum, the cost of going solar has gone down dramatically. And those lower solar prices are a boon for American manufacturers.

In many locations in the United States, going solar will save you money. Whether you own the solar array on your roof or enter into an agreement to purchase power from a solar array, it is common to pay less per kilowatt-hour (kWh) than purchasing power directly from the utility.

Installing solar also provides energy price certainty, giving you the ability to know exactly what you will pay for energy over the next 20 years. Solar power purchase agreements (PPAs) provide that certainty with a consistent rate regardless of utility rate hikes.

In addition to consistently lower energy pricing, installing solar has a direct impact on Scope 1 and 2 emissions. For companies tracking efforts to lower emissions, solar as an energy source has a significant impact on lowering a company’s overall carbon footprint. And even if your company is not tracking these emissions, by decreasing your facility’s carbon footprint you are making your goods and services more attractive to large corporate and government groups who purchase from you.

Retail stores and large corporate buyers are tracking upstream Scope 3 emissions from their supply chain. In 1999, 34% of the world’s top 250 companies reported on sustainability. In 2022, 96% of the top 250 companies reported on sustainability. Demonstrating a measurable lower carbon footprint provides an advantage to manufacturers when negotiating with customers.

Options to Go Solar

Going solar may seem daunting, but with the right partner it is a straightforward process. The right partner will provide you with your options, be forthcoming about the suitability of your roof or land, and most importantly – let you know if it does not make sense for your location to go solar.

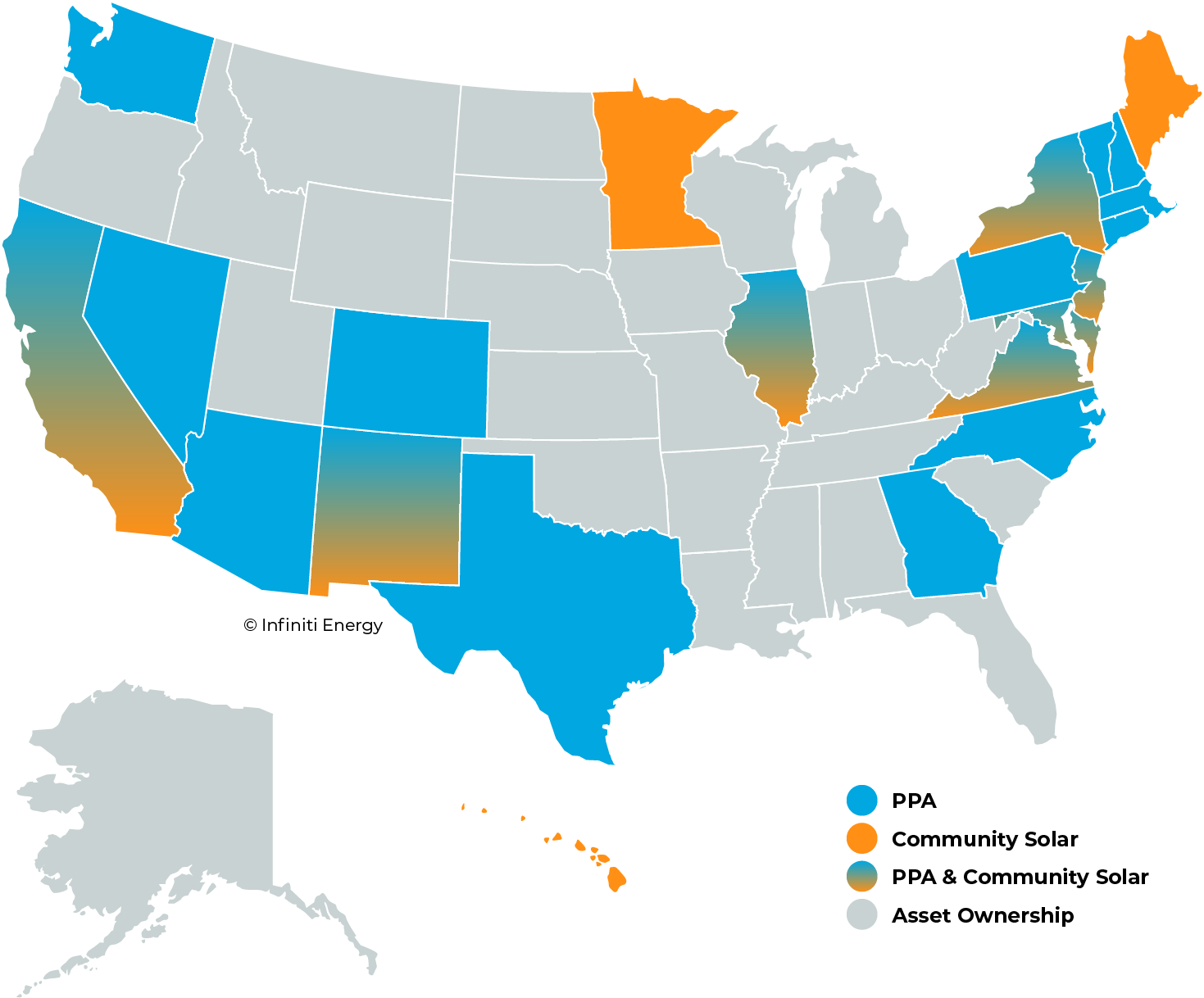

When going solar, your organization generally has three options to finance your solar array.

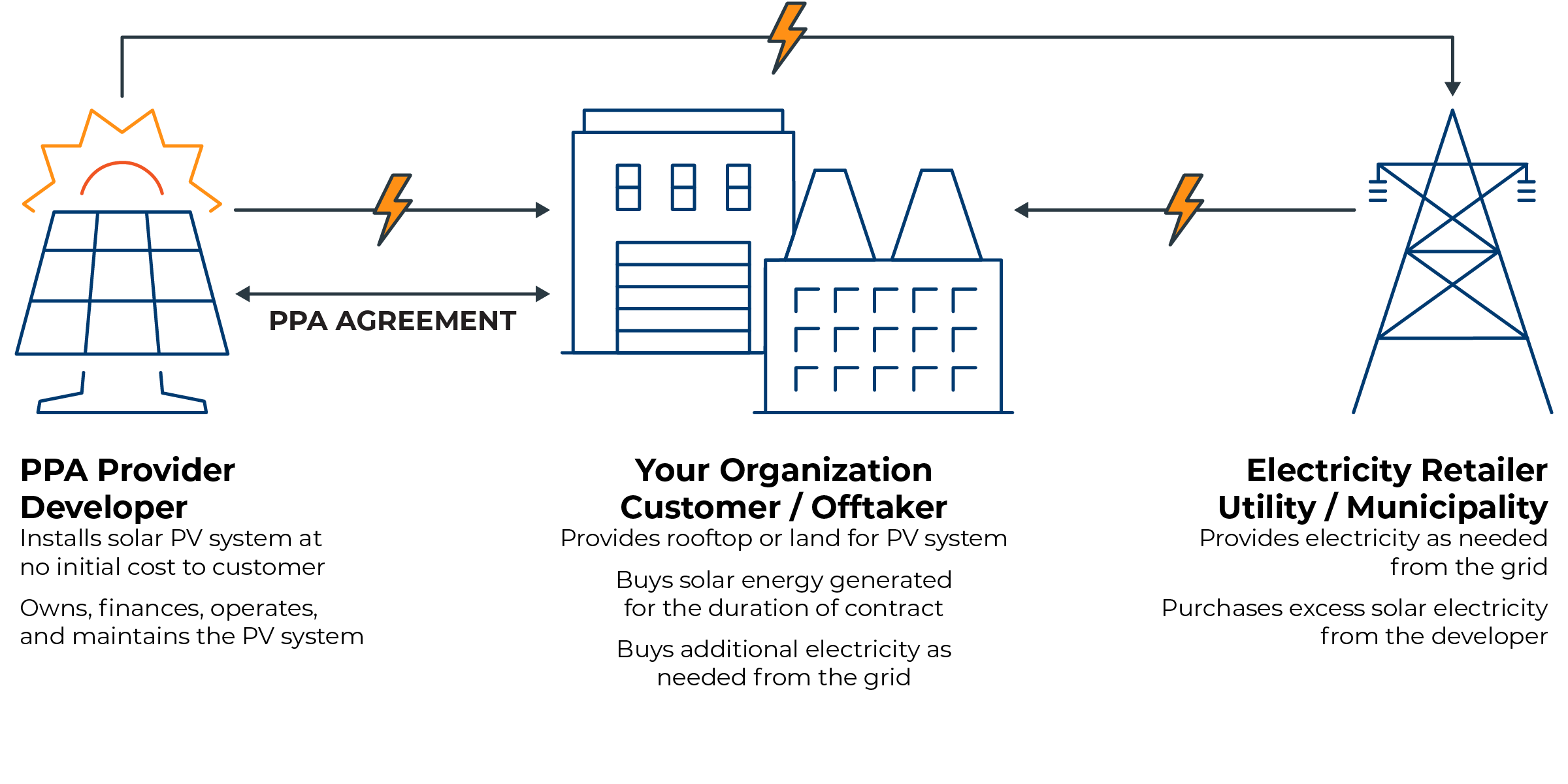

Power Purchase Agreement (PPA)

This option requires no capital expenditure and no O&M spend from the manufacturer. A solar PPA is the most common financing structure for industrial and manufacturing companies. The PPA provider/developer installs solar on the organization’s roof or land, owns the solar array, and is responsible for maintaining it. The organization, or offtaker, buys the energy produced at a lower price point than buying from the utility. The term of the contract gives the offtaker price certainty for the duration of the agreement.

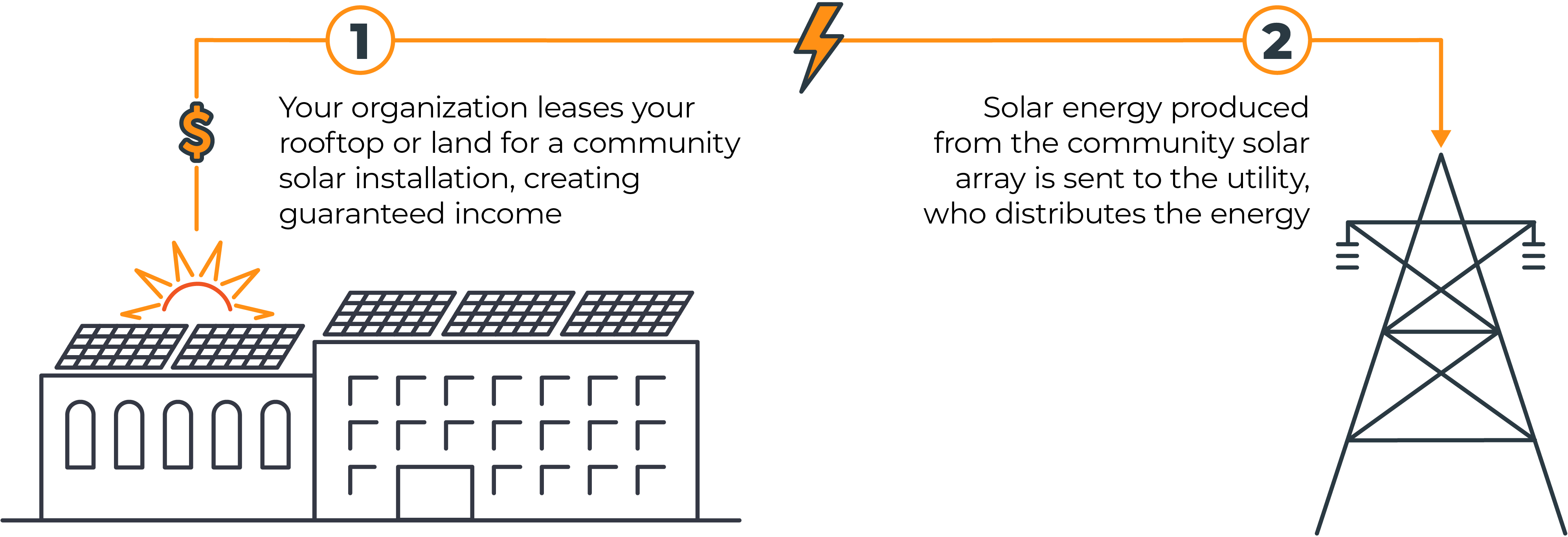

Community Solar

Community solar provides benefits to both the building/landowner and the community at large. In this arrangement, the financier/developer will lease roof space or land from the manufacturer for a solar array. The solar energy produced is sent to the utility, who then distributes the electricity. The manufacturer generates guaranteed income from the lease of their land or roof. And the community benefits from clean, solar power as part of their energy mix.

Asset Ownership

A company may choose to purchase a solar array outright, paying all upfront costs for equipment and installation. In this case, the company will own the solar array, consume the energy generated by the array, and benefit from any federal and state financial incentives. While asset ownership leads to essentially “free” energy once the investment reaches parity, considerations for organizations include the initial capital expenditure and ongoing operations and maintenance (O&M) responsibilities.

How Much Could You Save?

As the most common financing structure for industrial and manufacturing companies going solar, we have included three example PPAs below. Please note that these are examples only. Every situation is unique – location, roof/land space available, length of term, local, state, and national incentives all play a part in financing structures.

New Jersey Rooftop

100,000sf of usable rooftop

1 MW solar array

15-year PPA

Savings of 50 – 70%

over utility retail rates

Pennsylvania Rooftop

100,000sf of usable rooftop

1 MW solar array

Located in an “energy community”

20-year PPA

Savings of 30 – 40%

over utility retail rates

Illinois Rooftop

100,000sf of usable rooftop

1 MW solar array

20-year PPA

Savings of 10 – 30%

over utility retail rates

Infiniti Energy

Infiniti Energy, founded in 2015, provides solar development, engineering, procurement, & construction (EPC), project financing, and asset management for select commercial and industrial clients. Collectively, Infiniti personnel have over 600MW of combined experience in the public and private sectors including Fortune 100 portfolios and government entities.

Next Step

If you think solar might be right for your industrial/manufacturing facility, we encourage you to contact the Infiniti Energy team. We are happy to discuss specific projects or simply answer your questions about going solar.

Reach out today!